Tabakh mills

A profession inherited through generations for decades since 1870 in the city of Aleppo, the first large stone mill powered by animals was established, operating through circular motion with a wooden support. It was used to grind grains, then sift and purify them from impurities using manual sieves.

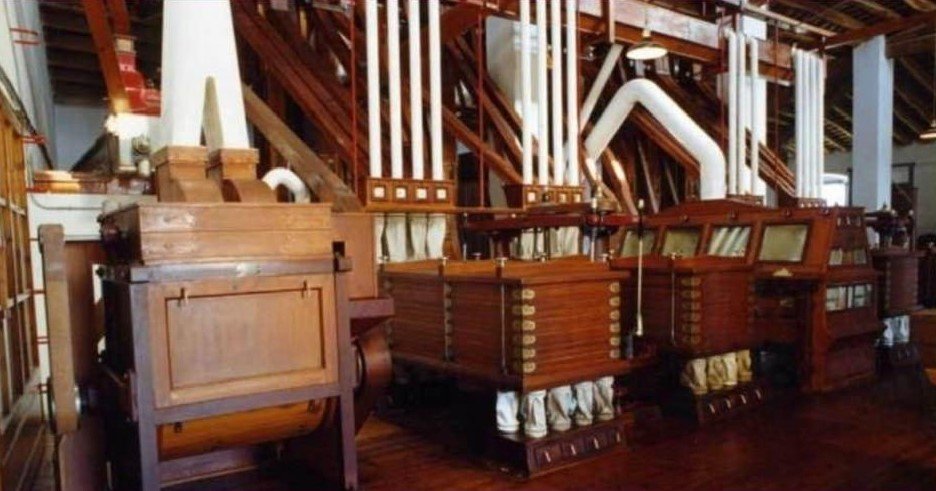

In 1930, after the introduction of electricity, the Al-Tabakh Mill in Aleppo province was modernized to become the first semi-automatic wooden mill. Through this mill, grains were purified from impurities, then ground and sifted using electric vibrators in several stages to produce various types of wheat flour, which were distributed in the markets.

With the advancement of industrial technology, the mill was fully automated in 1970 by adding several stages for purifying impurities, grinding, moisturizing, storage silos, and increasing production quantity and higher quality of flour.

In the year 2000, the mill was upgraded with the latest European machinery, which operates with modern grinding systems using metal cylinders, in addition to many stages of cleaning, sifting, filtering, and producing various types of wheat flour to achieve higher quality in baking. It was also equipped with quality analysis laboratories to select the best types of wheat before grinding. It continues to operate until today with a large production capacity, by the grace of God.

In 2013, the company expanded its operations internationally and established a modern mill in Turkey. The latest European machinery was utilized, along with a laboratory equipped with state-of-the-art global flour analysis systems and unique purification techniques. Wheat undergoes thorough examination before the milling process begins to meticulously test the finest varieties of wheat within international standards. These varieties contain high levels of protein and gluten, which play a significant role in producing the finest bakery products, pastries, and sweets. This is achieved by sorting the flour into multiple stages according to the buyer’s request and in alignment with business requirements. Additionally, enhancers, minerals, and vitamins can be added upon request, especially in areas experiencing displacement and nutritional deficiencies, to maintain high-quality bread and produce a nutritious product with numerous benefits.